About Ergonomics

Occupational Ergonomics is based on the approach by studying how people work given their abilities and knowledge to design equipment, jobs, work stations and end products.

The terms ergonomics and human factors have been used interchangeably. Ergonomics traditionally refers to the physical limits of the individual, how the work place design affects the person and the biomechanics of the work environment. It includes the physiological response to the physical workload and environmental conditions. (e.g. heat, noise, lighting, vibration).

Human factors engineering focus on how people interact with equipment, job demands, environment and work stations.

Priorities are easily defined by preventing occupational injuries, organizing their physical set-up and work methods. In addition ergonomists are improving worker efficiency and effectiveness while easing operator comfort. When working with manufacturing and operations personnel the goal is to identify current jobs with ergonomic-related risk factors and correct existing problems. When employee demand exceeds capability, physical injury and processing errors are more likely to occur.

Key principles of Ergonomics:

– Increases in employee salaries

– Limiting fatigue & injury potential

– Improving hand eye coordination for complex psychomotor & visual tasks

– Improving physical health & recovery from stressful job tasks

-Allowing employees to limit their exposures to environmental factors

– Decrease in workers’ compensation claims

Problem solving & ergonomic skills:

– Identify neutral postures & musculoskeletal disorders (MSD’s)

– Identify potential job risk factors

– Redesign hand tools with optimal grip & force components

– Implement job rotations & enlargement recommendations

– Understand the influence of Personal Protective Equipment (PPE)

– Improve productivity & limit human error

– Develop educational programs for employees & Health/Safety staff

There are six major areas of the human body that is necessary when evaluating an employee at their work station. This includes their size, functional strength, endurance levels, work environment, control factors and mental health aspects.

Lifting is the most common manual handling task in the Industrial setting.

*** The most important risk factor to be aware of when lifting an object is the horizontal distance of the object from your body.***

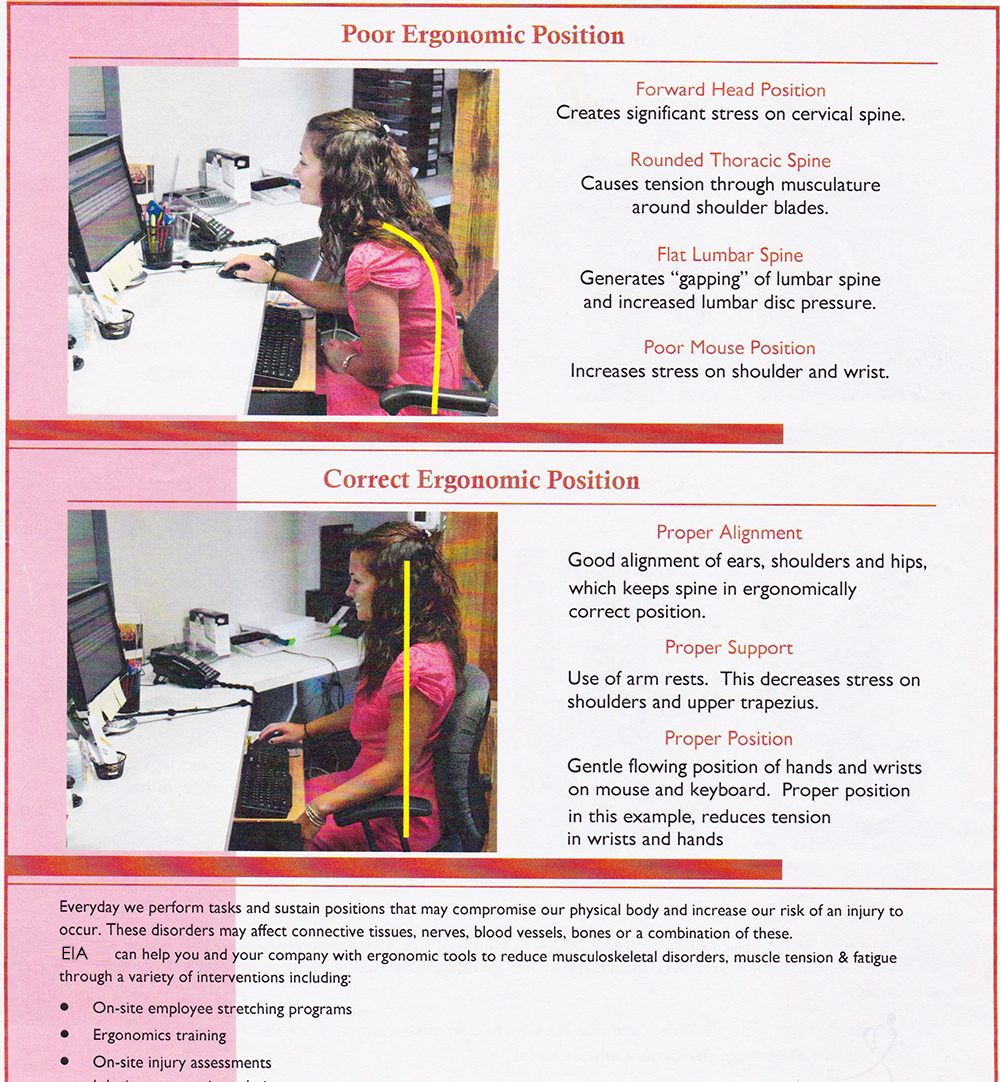

Improper lifting positions such as forward head, neck and shoulder posture and rounding your lower back will create an unstable base of support and contribute to a sudden acute or chronic injury to your spine and extremities.

Applying the correct lifting techniques is essential to reducing your potential risk in developing a musculoskeletal injury as long as you know your physical limits and capabilities.

Optimal goals when designing a work place and educating employees: Maintain your body in neutral posture and keep the elbows bent to 90 degrees as frequently possible. Position the shoulders back and down (retracted) while keeping loads close to your body when lifting and carrying. Always square your self off to the work at hand and never twist your lower back (lumbar spine).

Using stands to stack material off the floor while providing adequate work space and having the capacity to bring materials closer to the work station will decrease your risk factors.

Ergonomic Examples